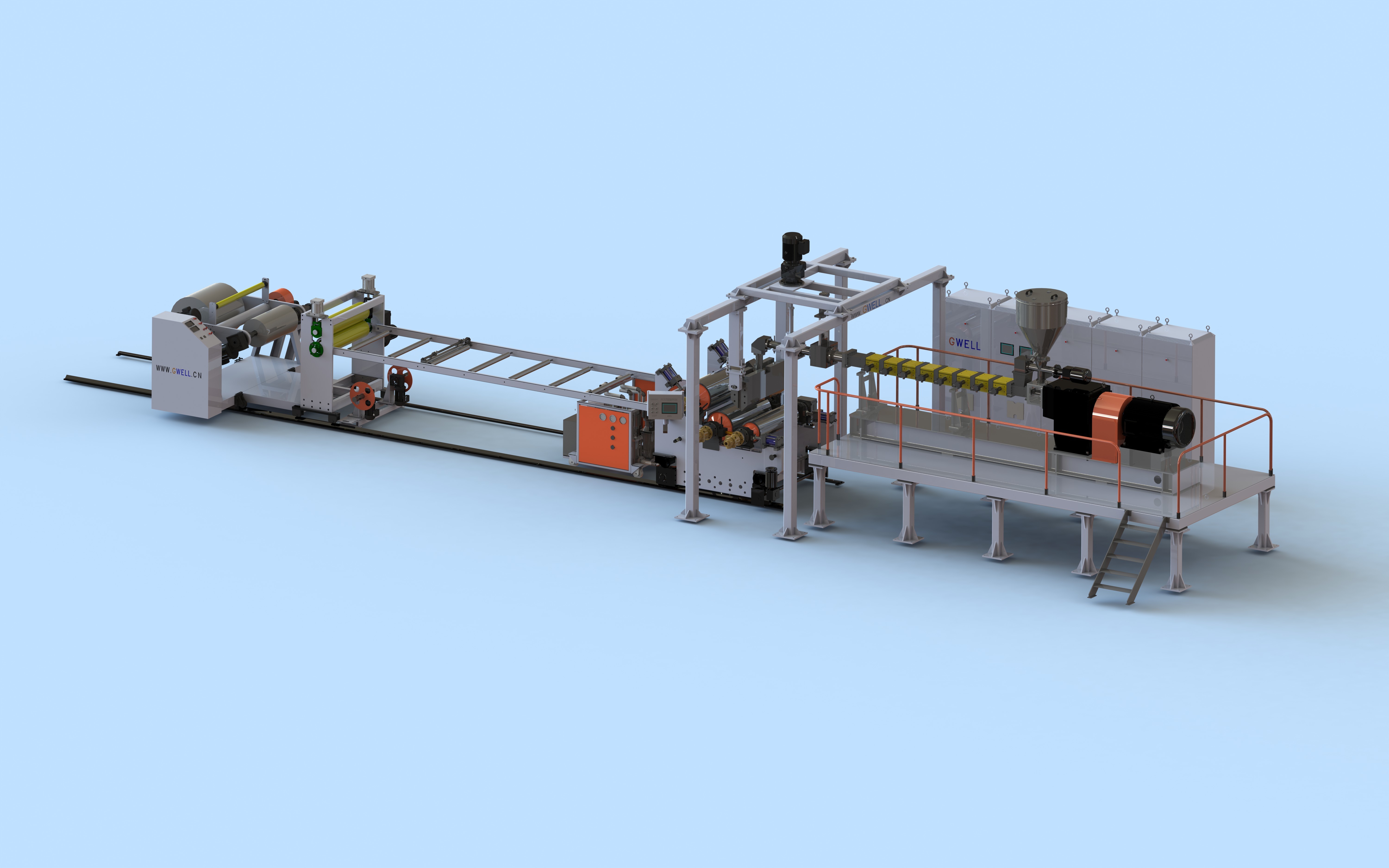

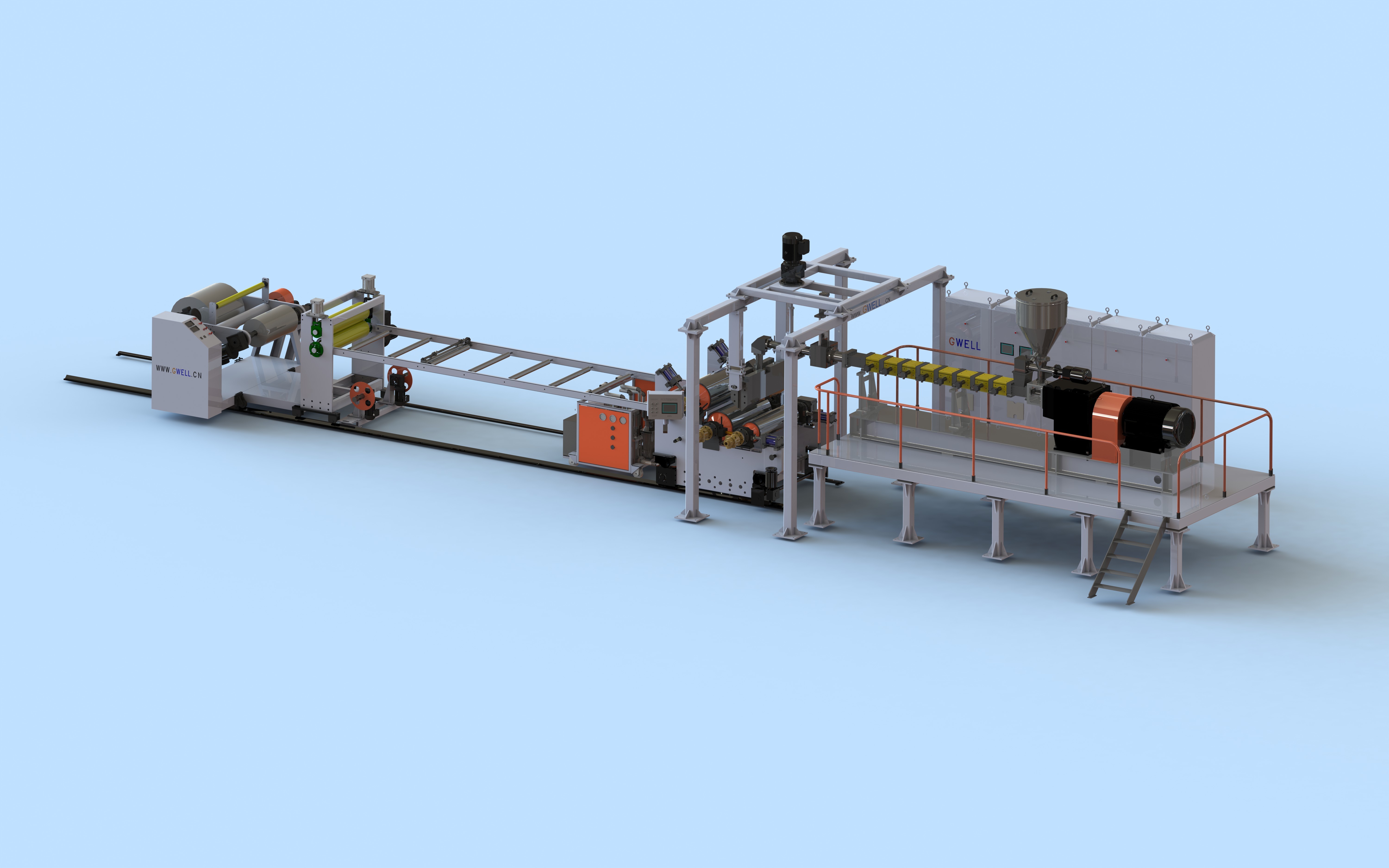

Introduce of PLA sheet production line: PLA sheet extrusion line

Also known as polylactide, belongs to the polyester family. Poly

(lactic acid) is a polymer obtained from the polymerization of

lactic acid as the main raw material, which is usually called corn

plastics. It has sufficient sources and can be regenerated. It is a

new type of biodegradable polyester material made from l-lactic

acid produced by corn and cassava through condensation, cracking,

purification, polymerization and other technological processes.

Pollution-free production process of poly (lactic acid) (PLA), and

the product can be biodegradable, implementation cycle in nature,

so it is the ideal green polymer material, and it also encourages

the development of high-tech environmental protection products. It

is widely used in electronic product shell, auto parts, medical

equipment, clothing fibers, agricultural plastic films, food

packaging, tableware, etc.

Gwell PLA sheet extrusion line is suitable for PLA(PLA) and

modified PLA. PLA is derived from plant resources and can be

directly used for extrusion molding. PLA and soluble PLA are widely

used in various food packaging and hardware packaging due to their

characteristics of biodegradability, composting and recycling.

Rollers can independent drive. The whole machine adopts PLC

control, automation of actual parameter setting, data operation,

feedback, alarm and other functions. PLA sheet extrusion line

1. Twin-screw combination technology PLA sheet extrusion line

Years of experience in R&D and design of twin-screw

configuration are optimized and combined with advanced software

technology. Special double-threaded elements and unique screw

combinations can realize conveying plasticization, mixing and

kneading, shearing and dispersing, homogenizing, exhausting,

pressure building and extrusion and various functions. Especially

for the removal of crystal water inside the PLA material, it has a

very high efficiency. The specially designed exhaust port does not

emit material, and is free and unobstructed. It realizes

low-temperature extrusion and avoids thermal degradation of PLA; PLA sheet extrusion line

2. Vacuum exhaust technology PLA sheet extrusion line

Multi-stage forced exhaust is efficient and safe to ensure that the

PLA material will not be hydrolyzed or crystallized during the

melting and plasticizing process. Special three-stage vacuum

exhaust technology and oil-gas separation technology, super large

pumping capacity and super high vacuum, greatly reduce the

viscosity reduction of PLA. PLA sheet extrusion line

3. Spiral flow channel technology inside the high-strength roller

The internal spiral flow channel structure design of the

high-strength roller is equipped with a water temperature control

system, so that the roller has precise temperature control and

efficient heat transfer effects;

Using multiple extruder co-extrusion technology to produce

multi-layer co-extrusion composite PP and PS sheets, such as AB,

ABA and other multi-layer structures, which are widely used in

thermoforming, printing, hardware packaging, electronic pallets,

flocking, Food, clothing, tools, toys, stationery pieces,

decorative pieces, etc.

* equipped with precise distributor, evenly layered, adjustable

proportion of each layer, digital precise control.

* inclined horizontal structure, easy to operate and maintain.

* roller independent power, linear speed and extruder speed

synchronous closed-loop control.

* the whole machine adopts PLC control to realize automatic control

of parameter setting, data operation, feedback, alarm and other

functions.

* Gwell independently wrote the electronic control operating system

PLA sheet extrusion line / PLA sheet extrusion line