Gwell plastic transparent sheet unit production line absorbs and

digest western country advanced extrusion technology. And its main

parts choose from all over the world (such as screw, barrel,

roller, etc.). The energy consumption of its complete sets of

equipment , intelligent, automation, safety standard, technology

standard, etc., have been at or near the world standard of the

product. This series of products has a number of inventions and

utility model patents so that it replaces imported equipment, and

has a cost-effective advantage. The high-level transparent plate

products are widely used in optics, home appliances, construction

engineering, decoration, furniture, advertising, handicrafts and

other industries and civil industries. Its quality has reached the

world's product performance, and we have a matching team of experts

and process engineers to help users debug, produce high-quality

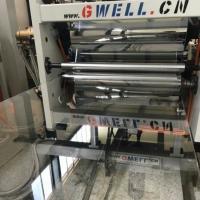

products.Horizontal Three-Roller Calender Used For Shaping Sheet Film

The three-roll calender is mainly used to calender the

high-temperature melt extruded from the cloth-hanger type mold and

maintain a certain thickness to form the required products.

According to the structure type, it can be divided into three

types: vertical type, inclined vertical type and horizontal type.

According to the three-roller transmission mode, it can be divided

into chain transmission, worm gear transmission and independent

transmission.

Users can comprehensively consider the selection according to the

products produced, operating habits and economy. Our company can

also undertake custom-made special three-roll calenders.

Inclined inclined type and cooling coiling auxiliary machine are

matched.

1. The roller of the calender adopts a jacket structure with high

exchange rate and is equipped with an automatic temperature control

hot water exchanger, with high temperature control accuracy and

uniform roller surface temperature; the working surface of the

roller is plated with hard chromium and processed by

ultra-precision mirror surface.

2. The reduction box is a hard-tooth surface combined gear box with

high transmission accuracy and smooth movement.

3. The roller is driven by a speed-adjusting motor and controlled

by an imported speed-adjusting controller; the speed can be

monotonous or linked according to the setting. The speed range is

wide and the precision is high.

4. The auxiliary machine adopts a bridge type slow cooling roller

table, and is equipped with trimming, waste collection, traction,

winding and other devices; it can also be equipped with embossing

device and fixed-length cutting machine to further expand the use

of the unit and the cooling and winding auxiliary machine.

4. Crusher models

| number | item | quantity | unit | Remark |

| 1 | Drive motor | 3 | Units | Power about 11KW |

| 2 | Roller | 3 | Units | |

| 3 | Gearbox | 3 | Units | |

| 4 | cooling system | 1 | Set | Water cooling |

| 5 | Other Accessories | 1 | Set | |

Gwell Machinery is a high-tech enterprise, committed to providing

customers with plastic sheet, board, film and other extrusion

lines. Gwell can provide turnkey projects, such as stone paper

project, EVA solar film project, PP building formwork

equipment,etc. Gwell has a strong technical equipment strength and

key capacity, committed to high-end product development,

international market development. “Realize customer value" is the

company's long-term business philosophy.The manufacturing bases of

the company are located in Taicang, Suzhou, which is close to the

beautiful scenery of Shanghai, Yancheng Dafeng, the hometown of

Red-crowned crane, and Nantong, the hometown of Education and

longevity in China. It covers a total area about 150,000 square

meters. It has an annual production capacity of more than 200

extrusion lines of various types of sheet and board.